Compatibility: For use with positive trigger OEM fuel system control modules (GM, MOPAR,, etc.) when using aftermarket stand-alone fuel pumps like the TI Automotive 340/450/525, Bosch, DeatchWerks, etc. Click here if you are using OEM fuel modules. For negative trigger systems (Ford) please contact us.

Fuel System Control Module (FSCM), Fuel Pump Pressure Module (FPPM), Fuel Pump Driver Module (FPDM), and Fuel Pressure Control Module (FPCM) are slightly different names for the same device. They electronically control the fuel pressure by pulsing the fuel pump on/off, typically at 25khz, hence turning it into a variable speed pump. The ECM commands a pressure, the FSCM provides the heavy lifting to power the pump, and the fuel pressure sensor provides feedback to the ECM. This excellent closed-loop control system is used to help adjust injector duty cycle based on actual injector delta pressure. No aftermarket system offered can perform this function. So, why get rid of it when “Going Big” with new pumps if it can still be useful?

The newest GM and Mopar engines and electronic control systems are some of the greatest automotive technology available today. But, like all gearheads, we usually want more, right?

Unfortunately, the OEM FSCM’s used in both the late model OEM car and in crate engine offerings leaves much to be desired when more fuel is needed. The OEM FSCM can handle one high-power pump, but not multiple pumps. For example, the GM FSCM for Gen5 systems has “22A Max” labeled on the internal circuit board. A single TI Automotive 525lph pump will require that much power. So, when trying to add another pump they will not be able to support the needed power and will start throwing MIL codes. So, how can more than one pump be used while still keeping full closed-loop control of the FSCM?

The Ally kit allows the GM, Mopar, or any other positive pulse FSCM to control the primary pump, while the VaporWorx Ally Auto-On controller “Piggybacks” and takes care of the other pumps. The Ally Auto-On does not turn on the other pumps until approximately 3-4psi of boost by using the engine MAP sensor or a VaporWorx supplied stand-alone MAP sensor as the turn-on trigger. Custom tunes are available at no extra charge. Please contact us for these options.

When used in this way there is sufficient power for all fuel pumps while maintaining the FSCM full CAN feedback and diagnostics. All pumps will effectively be under the control of the FSCM.

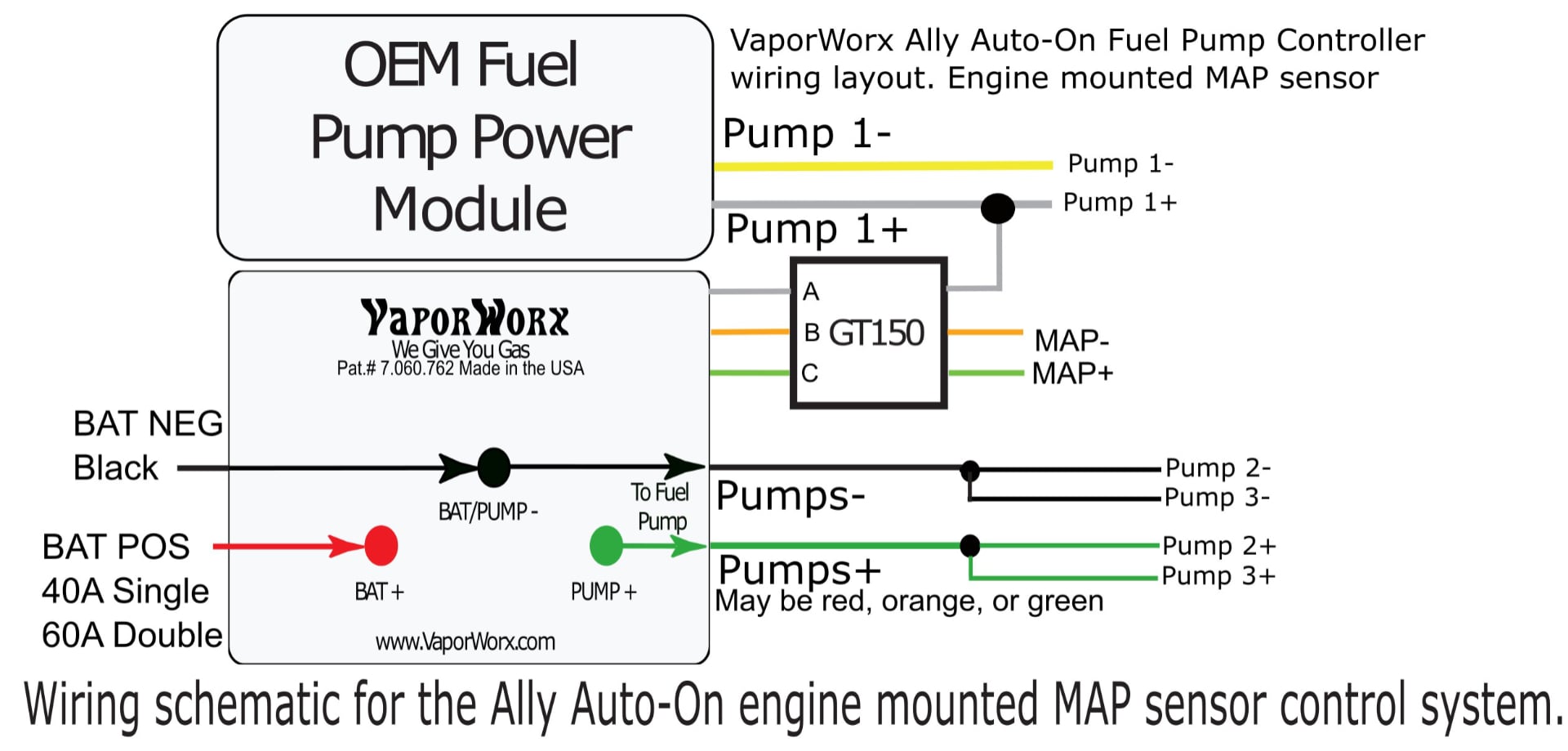

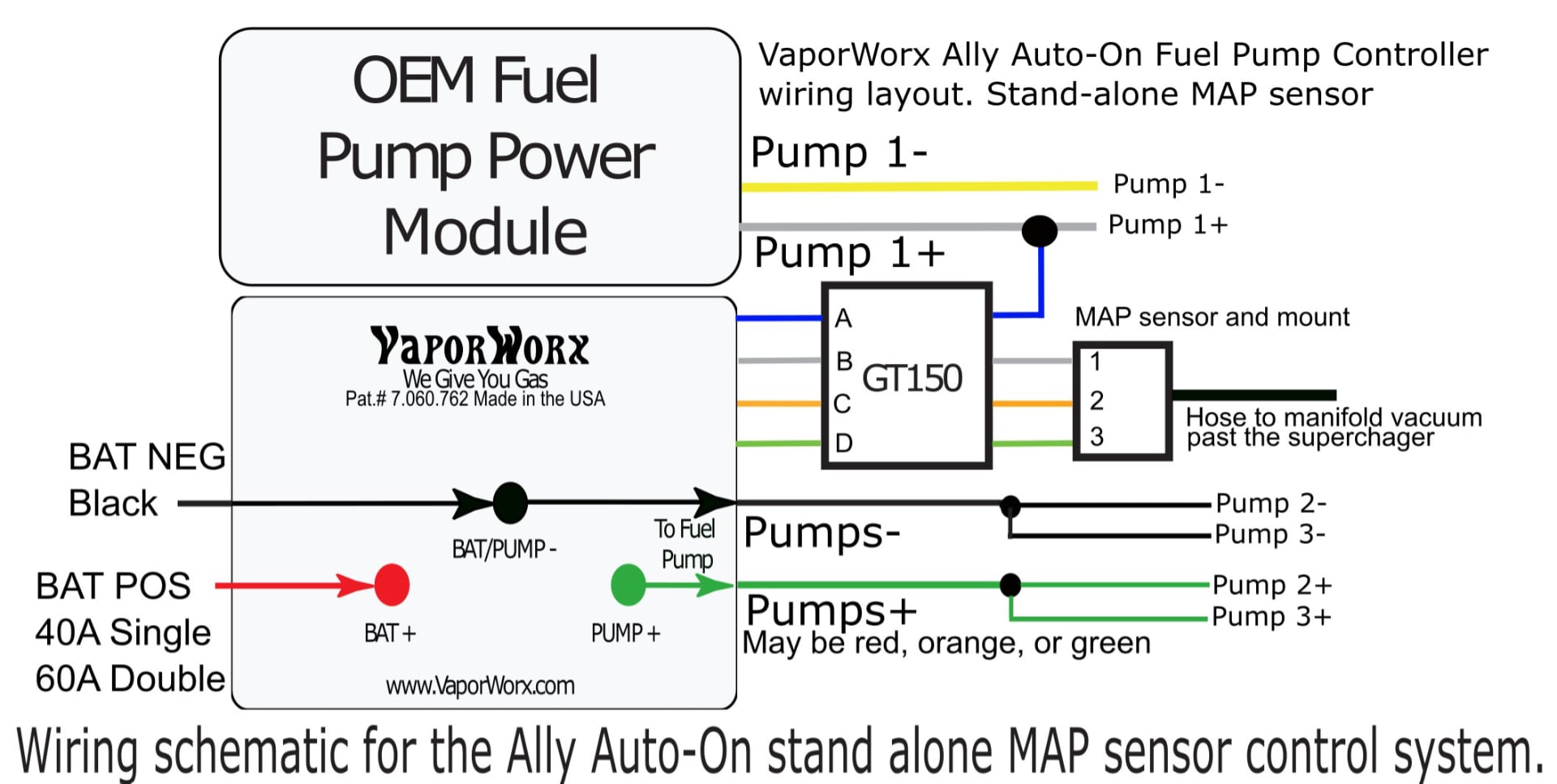

With just a single 20ga wire to attach to the FSCM fuel pump + wire, and the before mentioned MAP sensor wiring, hookup is straightforward. With that done, it’s just battery power in, and fuel pump power out. No Hobb’s switches, no relays, no on/off switches, etc.

A feature that the Ally controller offers that is not available on other control types is a progressive pump ramping strategy. In short, the FSCM’s have power envelopes they are expecting to work in. If the power is too high, it sets MIL codes. In order to reduce the chances of too much power setting a MIL code the VaporWorx controller will “outrun” the primary pump at higher duty cycles. This allows the VaporWorx controller, with the 2/3 pumps attached, to provide more fuel output than the primary FSCM pump. This helps keep the FSCM power load down and reducing the chances of a MIL code.

Another advantage to the Ally is a soft-start feature that reduces pressure spikes when the 2/3 pumps turn on. Traditional relay switches turn the pumps on full speed, often resulting in a fuel pressure spike. When the VaporWorx controller turns on the 2/3 pumps there is a very short soft-start ramp in to help reduce pressure spikes.

Which controller to choose if using the engine mounted MAP sensor for triggering the controller on/off?

The standard engine mounted 3bar controller turns on the 2/3 pumps when the MAP sensor output voltage is 2.15v.

LSA/LS9 sensors: This will turn on the controller at 3psi boost. Good choice for 340lph or larger primary pump.

LT4/LT5 sensors: This will turn on the controller at 9psi boost. Good choice for 450lph or larger primary pump. Specify when ordering that an LT4/LT5 sensor is used and VaporWorx will calibrate for a 3-4psi turn-on point.

Hellcat 68207074AA: This will turn on the controller at 0psi/ATM pressure. This may cause the auxiliary pumps to come on at key-on. Not suggested.

Demon/Hellephant 53010887AA sensor: This will turn on the controller at 4.5psi. Good choice for 450lph or larger primary pump.

The standard 2bar controller turns on the 2/3 pumps when the MAP sensor output voltage is 2.75v.

LSA/LS9 sensors: This will turn on the controller at 8.5psi boost.

LT4/LT5 sensors: This will turn on the controller at 13psi boost.

Hellcat 68207074AA: This will turn on the controller at 4psi/ATM pressure. Good choice for 450lph and larger primary pumps.

Demon/Hellephant 53010887AA sensor: This will turn on the controller at 3psi. Good choice for 450lph or larger primary pump.

Custom on/off turn on points for any MAP sensor is available. Just contact us.

If you’re thinking of future power upgrades (and who isn’t?), this kit will control one or two fuel extra pumps. In other words, if only one extra pump is needed today, another can be added later by just hooking up the extra positive and negative pigtail. No other modifications needed.

Features of the kit include:

- Everything needed electrically to drive the 2/3 fuel pumps. No hard to get connectors, multiple fuses, Hobb’s switches, etc.

- A 2/3 reduction in power to the fuel pump during idle and cruise vs traditional systems means long OEM pump life expectancy.

- 50A minimum continuous power rating in a compact controller package. Total size 4”L x 2.1”W x 1-5/8”H.

- Progressive 2/3 pump ramping strategy lowers the load on the FSCM to reduce MIL codes.

- Soft-start feature to reduce initial pump-on pressure spikes.

- Can use either the engine MAP sensor or a VaporWorx stand-alone MAP sensor.

- Over-temperature shutdown with automatic reset.

- Short circuit protection that will operate indefinitely without damage.

- OEM Delphi/Aptiv connections for terminals, seals, and connector bodies where appropriate.

- Cross-linked polyethylene wiring.

- UL94 rated components used throughout.

- Allows all the OEM ECM priming and safety systems to remain functional.

- Can be used with one or two extra/auxiliary pumps.

- 10-22v operating capacity.

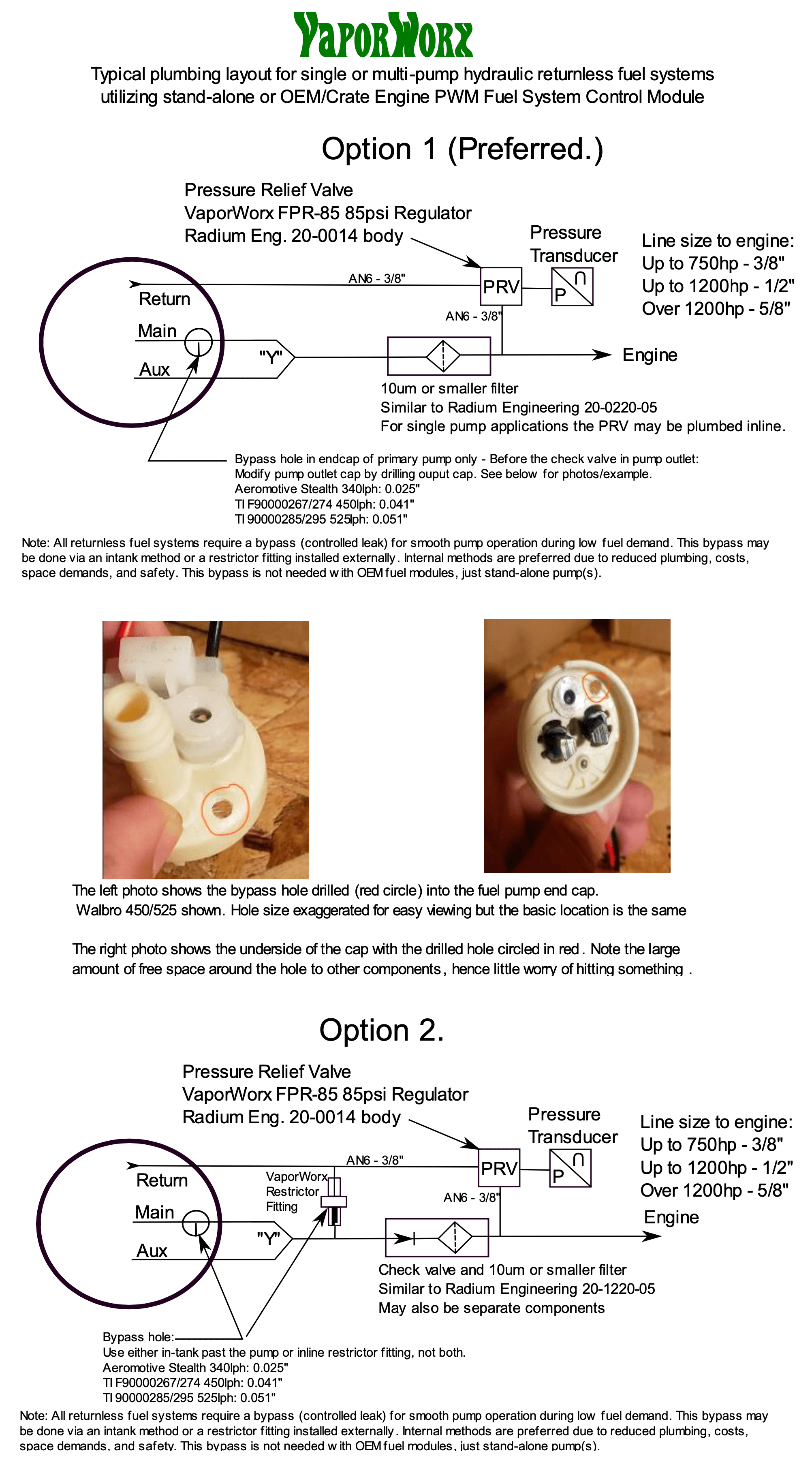

Below are the basic layout diagrams for the engine mounted MAP sensor, stand-alone MAP sensor, and plumbing layout.

NOTE: Do not combine the pump grounds/low reference wiring. The FSCM ground wiring MUST remain separate and not be connected to anything else. The FSCM monitors the ground side, and if connected to ground will detect a short-to-ground fault.

SKU: PWALLY-AO

This product has dedicated documentation available:

Click the button to view the documentation, or click here for download options.

Specialized additional documentation also available:

This product has the following specialized additional instructions available to download, which not specific to the kit itself:

Modifying the Fore Innovations Pump Support for Returnless Systems

NEW! Find your perfect PWM Controller Kit

It’s easier than ever to be sure you’re getting the right PWM Controller Kit for your build! Click the button below to try out our new PWM Controller Kit Selection Tool and find the perfect kit, specifically compatible with your application, based on the options you select.