The PressureWorx fuel module control system has everything needed to provide a stand-alone, OE-type returnless fuel system.

When used with the low-cost GM, Ford, and many other OEM returnless PWM controlled fuel modules, the system can provide a constant pressure or any base pressure with a 1:1 manifold referenced (MAP sensor based) fuel pressure. It will act just like a mechanical fuel pressure regulator would with the ECM tuned in the same manner. The fuel injector does not know if the fuel supplied is pumped by a return or returnless system.

If manifold referenced fuel pressure is to be used, the standard PressureWorx option is tuned for the GM LSA 3bar 12592525 sensor. Other sensor tunes are available at no charge. The MAP sensor tune in the PressureWorx controller must match the MAP sensor so that the proper 1:1 pressure rate change can occur.

Suggestion: If your car is already running with a constant pressure tune, and all you need is a larger volume fuel system, changing to MAP referenced fuel pressure is not needed or worth the extra expense to retune the fuel maps in the ECM.

Base fuel pressures at idle are typically between 42-60psi, but the VaporWorx controller has much greater range if needed.

For a constant fuel pressure system, like that for all GM naturally aspirated LS and LT series engines, a 60psi pressure is typically used. For supercharged applications, either a constant or MAP referenced fuel pressure can be used depending on how the ECM is tuned.

VaporWorx recommends using a MAP referenced fuel pressure on large fuel injected systems to allow injector duty cycles to be increased at idle/cruise, hence allowing greater tuning capability. MAP referenced fuel pressure also reduces the at idle power requirements by 2/3 vs traditional return type fuel systems.

It is strongly suggested to NOT use an inline filter with with OEM fuel modules except Gen3 Coyote GT500. Final filtering is built in. Some aftermarket fuel filters have a built-in check valve which will cause a heat-soak related overpressure condition that will lock up port type fuel injectors.

All OEM type fuel modules will not work on carbureted applications. A minimum 43psi is needed for proper WOT operation.

The PressureWorx Fuel Module Controller system includes these standard features:

- Everything needed electrically to drive the fuel pump module. No relays, external regulators, or return lines needed.

- Unmatched low fuel level capability when used with an OEM style fuel module.

- Up to 2/3 reduction in power to the fuel module during idle and cruise vs traditional systems.

- 40A minimum continuous power rating in a compact controller package. Total size 4”L x 2.1”W x 1-5/8”H.

- Compatible with the OEM CTS-V2 installed pumps, ACDELCO M10235. For DW300, AEM, and other higher output pumps, select the DW300C PWM Kit.

- Can be used with ZL1 fuel modules without the OEM fuel level sensor attached.

- 35-65psi operating range (range limited by fuel module).

- Over-temperature shutdown with automatic reset that will operate indefinitely without damage.

- Short circuit protection that will operate indefinitely without damage.

- OEM Delphi/Aptiv connections for terminals, seals, and connector bodies where appropriate.

- All cross-linked polyethylene wiring.

- 20′ wiring harness from the controller to the fuel module.

- UL94 rated components used throughout.

- Integrates into the OE ECM to allow all safety systems to remain functional.

- 10-22v operating capacity. Can be used with voltage boosters. The preferred booster is the JMS FuelMax. Lower than 10v applied to the turn on circuit will cause controller shutdown to protect from an AFR lean condition.

- Can be used in constant or manifold referenced fuel pressure modes. Manifold referenced suggested to further reduce electrical demand and for vehicles with large, 100#/hr+, injectors.

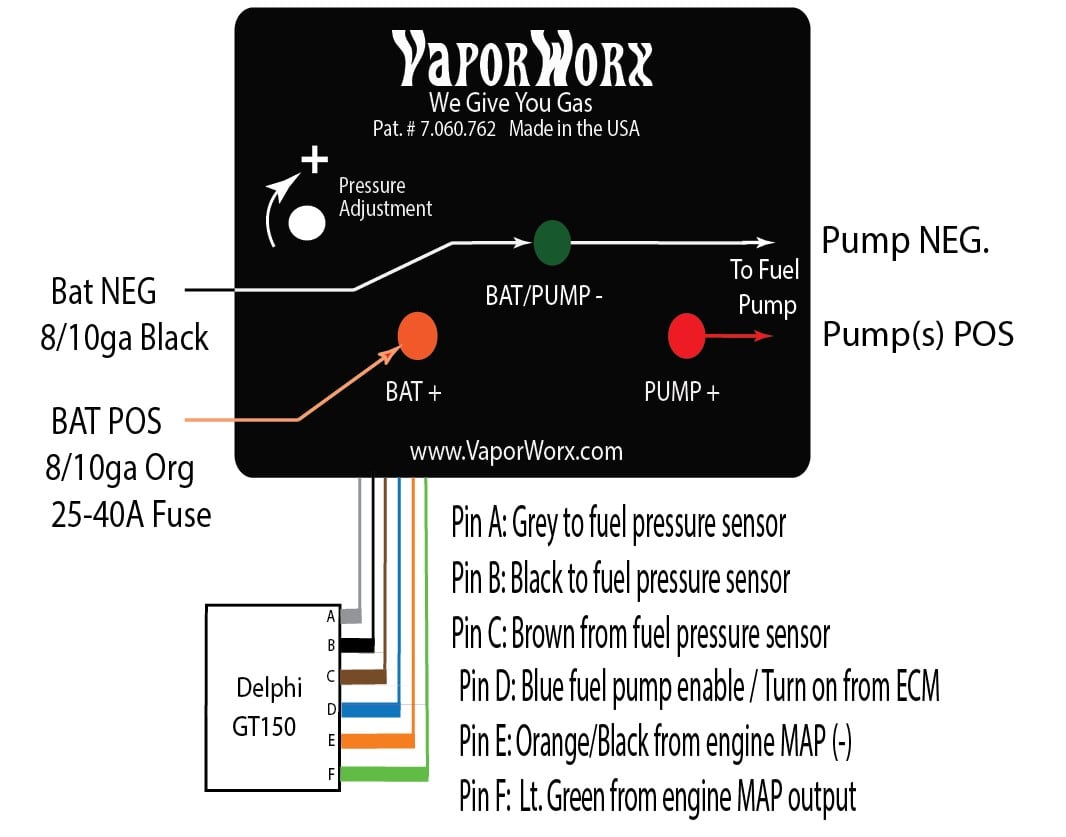

The basic wiring layout and connections are shown in the following diagram:

SKU: PWCTSV3B

This product has dedicated documentation available:

Click the button to view the documentation, or click here for download options.

NEW! Find your perfect PWM Controller Kit

It’s easier than ever to be sure you’re getting the right PWM Controller Kit for your build! Click the button below to try out our new PWM Controller Kit Selection Tool and find the perfect kit, specifically compatible with your application, based on the options you select.