Compatibility: Intended for use in modern OEM vehicles or aftermarket ECM systems that have a Fuel System Control Module (FSCM) where a Gen5 Camaro/SS/CTS-V type fuel pump module can be used. For vehicles that do not have a Fuel System control module please check the VaporWorx stand-alone control system for the KPM1500 fuel pump.

This kit does not include the KPM1500 fuel pump. It does include the necessary parts to modify the KPM1500 to make it work properly for FSCM equipped vehicles and aftermarket ECM/FSCM systems.

The latest KPM1500 fuel pump from our Aussie friends is, in our opinion, the best high-power aftermarket Gen 5 Camaro/SS/CTS-V2/etc. fuel module available today. With twin Bosch PWM compatible OEM pumps, fully re-engineered pump support system, robust venturi pumps, integral safety overpressure valves, and a built-in anti-reversion/check valve, it almost has all of the features that make it very much like an OEM part. Why almost, and why 1000fwhp and not 1500fwhp? VaporWorx is going to do you a solid and share the reality of this fuel pump, the engineering behind it, and why that matters. We’re not just doing a copy/paste and re-selling an item, but instead sharing the engineering work and providing the solutions to make it work properly under high fuel pressures.

Want to learn more about how OEM fuel modules work? Check out our video here:

Let’s get what appears to be the obvious out of the way. Yes, the KPM1500 is intended to be a direct fitment replacement for the Gen5 Camaro/SS and others of a similar type. One very nice feature that is often overlooked in this KPM design (nothing is shared with the OEM part, KPM designed the whole enchilada here) is that the outlet nipple has been strengthened to reduce the chances of breakage. It’s a small but thoughtful upgrade.

VaporWorx has been testing and developing the supporting electronics and mechanical parts to properly support the KPM1500 for the American market since very early 2024. Why the American market? Let’s first list a few characteristics of the as-supplied KPM1500:

- Both high-power Bosch pumps have no integral check valve. Due to the short height available in the Gen5/SS/CTS-V2 etc. type module, a traditional pump with a barb connection cannot be used. Since both pumps tie into a common manifold, if one pump is not running it will become a leak, hence making little fuel pressure. Both pumps running full speed requires 39A. Running both pumps full speed all the time may lead to vapor lock/cavitation, excessive noise and pump wear, and large electrical system demand. No modern OEM vehicle runs high-power pumps at full speed all the time.

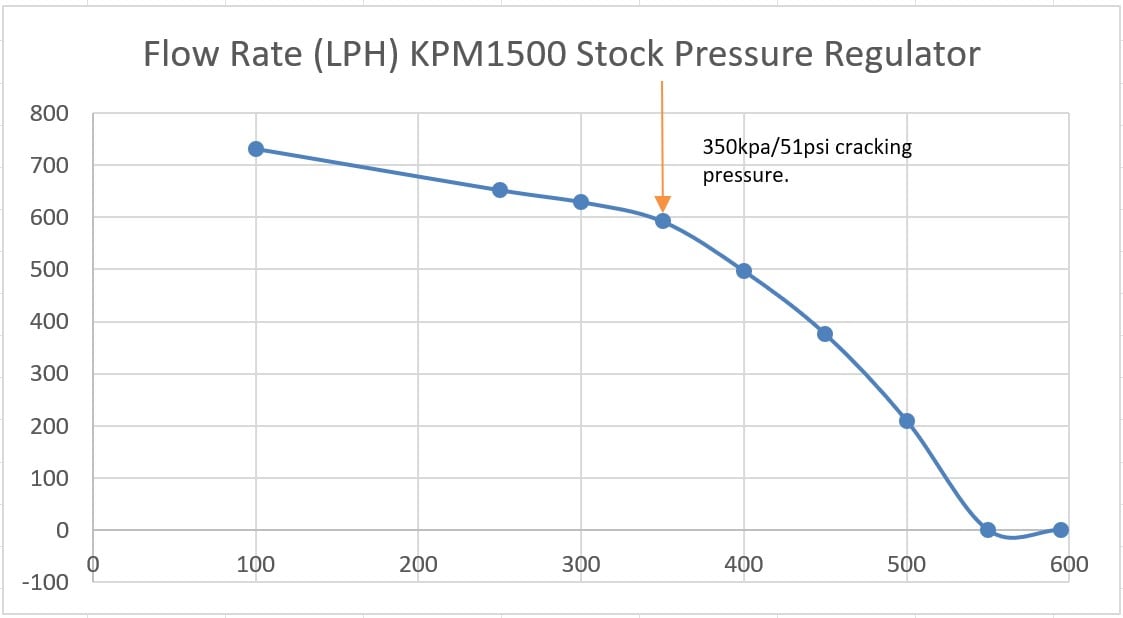

- The now integral pressure regulator cracks at 350ksp/51psi and is fully deployed at 550kpa/80psi.

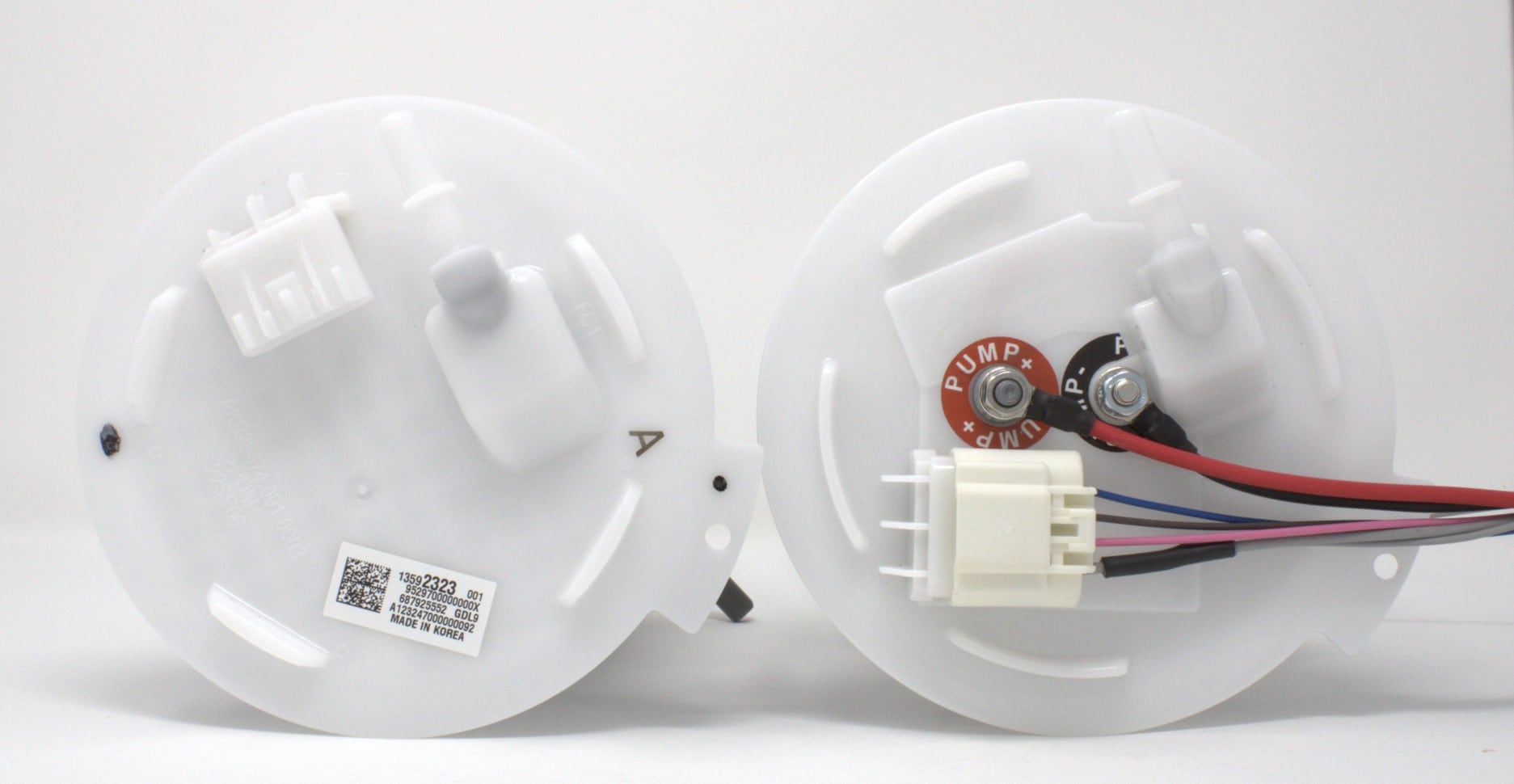

- In order to maintain the option of using the OEM fuel level sensor and to have the FSCM not throw MIL codes a ground and power lug for the second pump is needed on the bulkhead hat.

- Our Aussie friends tend to run low fuel pressures and very large injectors. Hence, the 350kpa/51psi internal regulator. In the USA, we tend to use higher fuel pressures typically in the 60-65psi range, plus that is typically where the OEM FSCM’s are programmed to operate.

So, let’s take a look at the pumping performance of the as-supplied by KPM 350kpa/51psi regulator:

Note how at 350kpa/51psi the graph “knees” downward. This is the point where the internal pressure regulator cracks open and starts returning fuel to the module reservoir. Also note that the pressure is 550kpa/80psi maximum. This means that at idle/cruise the fuel pressure is 80psi and falls at a non-linear rate. An external regulator will be of little use since two pressure regulators would be in play with both sending fuel back to the tank and not to the engine.

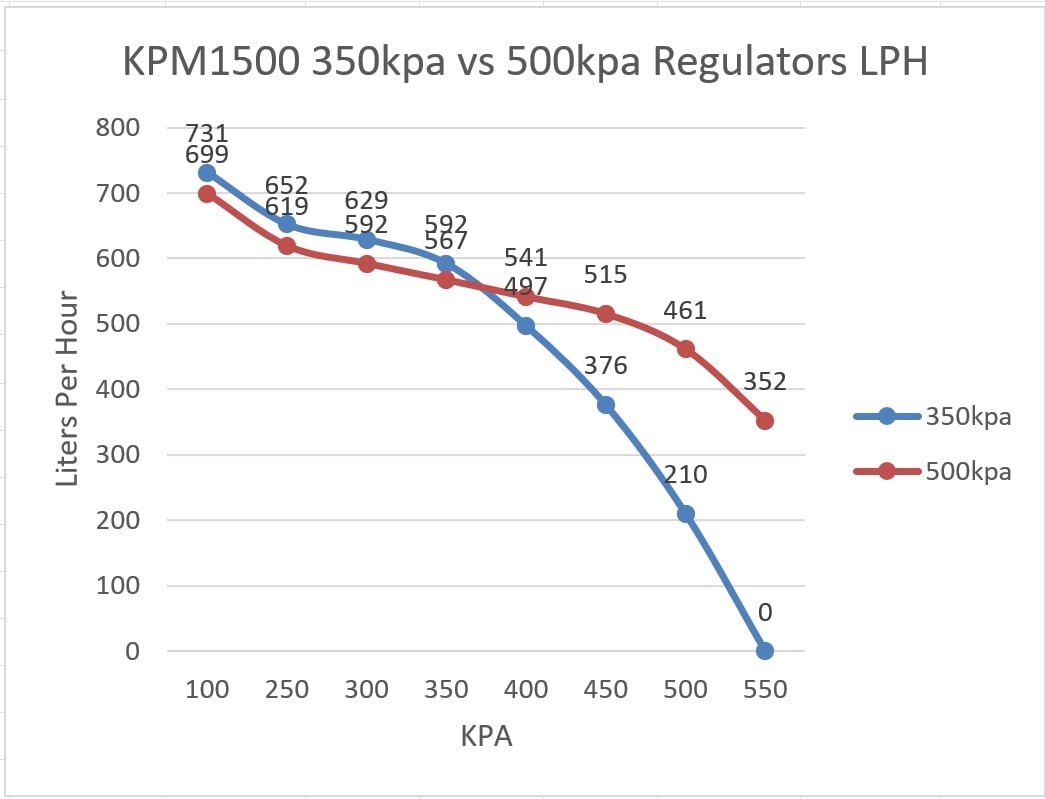

The VaporWorx version of KPM1500 replaces the low-pressure regulator with a high-pressure type. This allows pressure regulation similar to that in the Gen5/SS/similar OEM fuel module types. How much difference does this really make? How about a 37% increase at 65psi?

All flowrate data supplied by KPM.

Why the difference in flowrates at the lower pressures when both regulators are fully closed? The 350kpa/51psi graph is an average of the flowrates from 20 KPM1500 pump assemblies while the 500kpa is from a single pump assembly. It is common to have +/- 5% flowrate differences between pumps.

In the OEM FSCM equipped vehicle, pressure regulation is performed by changing the speed of the fuel pump to meet the commanded pressure. The FSCM is an electronic pressure regulator. The pressure regulator that is built into the OEM fuel pump module is a safety device for two reasons:

1) Heat soak at key off will cause line pressure to go over 200psi on hot days. That is not good for lines and fittings.

2) Once the line pressure reaches about 100psi the port injectors stop working as they cannot overcome the high pressure.

Hence, the mechanical safety overpressure valve built into the fuel pump also gives the KPM1500 higher flowrate at pressures above about 350kpa/51psi.

At VaporWorx we look very hard at what the OEM’s do since their engineering and development far exceeds anything in the aftermarket. Plus, let’s face it, these electronics cost far more than a simple regulator, so if the FSCM and their related parts make it on to the car they earned their way through the ruthless bean counters reviewing every part that costs money. Every OEM on planet Earth uses an FSCM on high-power pumping systems. That says something.

However, the weakness of the OEM FSCM is power capability. They can drive one high-power pump, but not two.

The cure? The VaporWorx KMP1500 Ally Pulse Width Modulation kit. To learn more about PWM, please visit our Resources section here.

This kit contains everything needed to drive the second KPM1500 fuel pump electrically while the FSCM handles the primary. This keeps the power separated but control of both pumps is handled by the FSCM. All of the feedback, diagnostics, fuel pressure, etc. remains functional. No Hobb’s switches, relays, pressure spikes, etc. All the Ally needs is battery power in, power to the pump, and a single small wire tied into the FSCM fuel pump positive wire. Compared to running both pumps full speed at 400kpa/58psi the VaporWorx Ally and the OEM FSCM reduces power to the pumps by 71% during idle/cruise.

Since both pumps run at all time in the KPM1500 fuel pump module, using PWM to slow down the pumps is very effective in keeping fuel temperatures down and relieving the electrical system of excessive load. Testing has shown that PWM control at typical idle/cruise pressure (60psi) and flowrates shows power reducing from 495w to 126 watts, a 71% reduction in power.

Another feature of the Ally controller is a unique control strategy that helps reduce the amount of power that the FSCM at higher fuel demand. The VaporWorx controller can comfortably handle, and is rated for, 60A. Hence, at higher duty cycles the VaporWorx controller will start to out-run the FSCM and take more of the pumping power load. This is seamless and transparent to the FSCM, it won’t even know the VaporWorx controller is helping out.

Just like a well tuned engine, fuel pumps under PWM operation all have a different sound. Like its predecessor, The KPM1500 is one the smoothest, quietest, and easiest to control systems that VaporWorx has ever tested for a system of this capability. Only the mid-2000’s Ford Mustang returnless pump is smoother, but that is a light-duty single pump, and it’s not much better. The KPM1500 just “sings” with the OEM level Bosch pumps.

This kit is specifically made for the latest KPM1500, not the Streetfighter 1500. It is intended to be used as an Ally, or piggyback, system to help the OEM FSCM. No additional relays, Hobb’s switches, etc. are needed. For cars that need a stand-alone KPM1500 control system please see the VaporWorx KPM1500 Stand Alone kit.

Features of the VaporWorx PressureWorx KPM1500 include:

- All the parts to convert your KPM1500 for use in a returnless PWM FSCM controlled vehicle.

- Everything needed electrically to drive the KPM1500 fuel pump in a piggyback/helper mode to support a positive pulse OEM Fuel System Control Module.

- Approximate 71%+ reduction in power to the fuel pump during idle/cruise vs running both pumps full speed all the time. Practically eliminates vaporlock/cavitation caused by overheated fuel.

- Fully returnless. External inline filter required.

- 60A minimum continuous power rating in a compact controller package. Total size 4”L x 2.1”W x 1-5/8”H.

- Over-temperature shutdown with automatic reset that will operate indefinitely without damage..

- Short circuit protection that will operate indefinitely without damage.

- OEM Delphi/Aptiv connections for terminals, seals, and connector bodies where appropriate.

- All cross-linked polyethylene wiring.

- UL94 rated components used throughout.

SKU: PWKPM1500-ALLYNP

This product has dedicated documentation available:

Click the button to view the documentation, or click here for download options.

NEW! Find your perfect PWM Controller Kit

It’s easier than ever to be sure you’re getting the right PWM Controller Kit for your build! Click the button below to try out our new PWM Controller Kit Selection Tool and find the perfect kit, specifically compatible with your application, based on the options you select.