VaporWorx Fuel Pump Speed Control Systems

In Part 8: How Do PWM Returnless Fuel Systems Work?, the concept of using pulse width modulation to control the speed of a fuel pump was discussed.

As a refresher, the idea is to turn the electric pump on and off very quickly so that the motor speed is sufficient to provide the needed pressure.

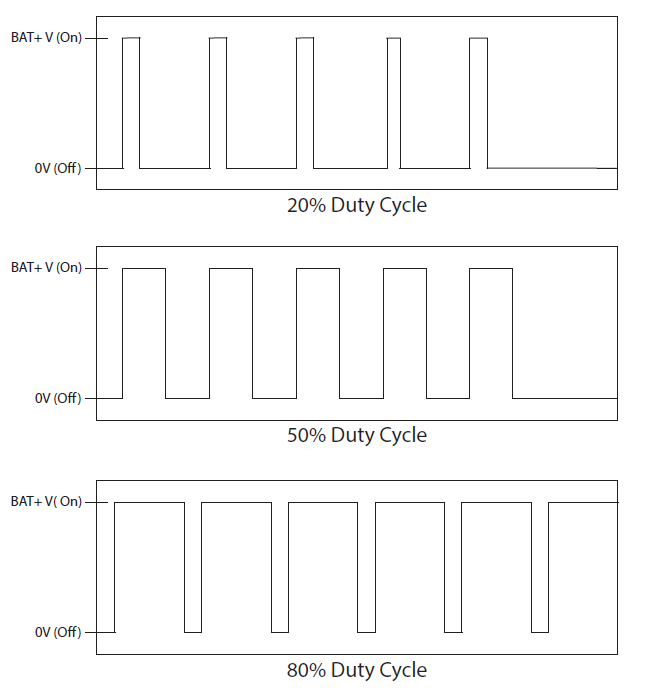

The length of time the pump is on is called the duty cycle. Shown in Figure 1 are some typical duty cycle waveforms:

Figure 1. Typical PWM signals that the fuel pump would operate under.

Key Concepts:

- Use a fuel pressure sensor for feedback.

- As the voltage from the pressure sensor changes, so does the pump speed.

- As the fuel pressure falls, the pump speed increases to meet the targeted setting.

- As the fuel pressure increases, the pump speed decreases to meet the targeted setting.

- If manifold referenced fuel pressure is needed then MAP sensor voltage can be used to provide a variety of pressure requirements.

VaporWorx manufactures a variety of controllers to perform these functions and much more.

Some examples of the types of control systems VaporWorx can provide are:

- Simple, single fuel module PWM pump speed controllers.

- Dual OEM fuel module controllers (ultimate high-horsepower fuel delivery systems).

- Dual and triple aftermarket fuel pump controllers (automatic turn-on functions).

- Piggyback controllers that allow the use of high-power modules and aftermarket pumps with OEM fuel system control modules with closed loop operation.

- Model specific controllers for engine and vehicle specific applications such as the GM LSA crate engine ECM, Pontiac G8, and Ford Gen1-3 Coyote crate engine ECM’s.

All controller kits, most of which are designated as PressureWorx or BoostWorx, contain everything needed to drive the fuel pump(s) electrically.

You can browse all our controller kits, categorized by either model/engine type, or by fuel pump/fuel module type.

NEW! VaporWorx has recently developed a PWM Controller Kit Selection Tool, which will show you a full list of compatible PWM Controller Kits based on your engine type and/or fuel pump/fuel module.

Click here to use our selection tool to find the best kit for you.

Different Control Strategies for OEM Fuel Modules and an Aftermarket Pumps

As a way of differentiating the controllers and to help clarify the differences, an OEM fuel module and an aftermarket pump require two different control strategies.

Examples:

OEM fuel modules supported include:

- Gen5/6 Camaro (all versions) and CTS-V3

- Cadillac CTS-V2

- Corvette C7

- GM trucks originally equipped with a fuel system control module (FSCM)

- Mustang 2004-14 S197 with OEM Fuel Pump Driver Module

- Mustang or other 5.0L & 5.2L

- Many others

Fuel pumps:

- TI 450 and 525LPH (F90000268 and F90000285, respectively) – Dual and triple

- Stealth 340 in single, dual, and triple

- Bosch -044 in single, dual, and triple

The fuel module is a larger, more complex device, but has features that no aftermarket pump can come even close to matching.

VaporWorx highly suggests whenever possible to use an OEM fuel module due to their far superior low liquid level fuel delivery performance, long life, and all-in-one design.

All PressureWorx and BoostWorx kits are designed to be a standalone controller, and can be operated in either constant/static or manifold referenced fuel pressure modes. To operate in constant pressure, just leave the wiring for the MAP sensor disconnected. Since there is no voltage change sensed on the MAP sensor wiring input, there is no pressure change.

A typical PWM kit for a ZL1 fuel module is shown in Photo 1.

Photo 1. This kit includes all of the components necessary to drive the Gen5/6 SS and ZL1 fuel modules electrically. The minimum power rating for a single output PWM controller is 50A, more than 2x that of some other systems. Higher power systems are available from VaporWorx for dual and triple pump systems.

Photo 1. This kit includes all of the components necessary to drive the Gen5/6 SS and ZL1 fuel modules electrically. The minimum power rating for a single output PWM controller is 50A, more than 2x that of some other systems. Higher power systems are available from VaporWorx for dual and triple pump systems.

(Click the image to zoom in)

With the use of the OEM fuel module no external filters are needed (except the S197 Mustang), nor are any external regulators or return lines. Using the VaporWorx PWM system becomes a smart electronic fuel pressure regulation system.

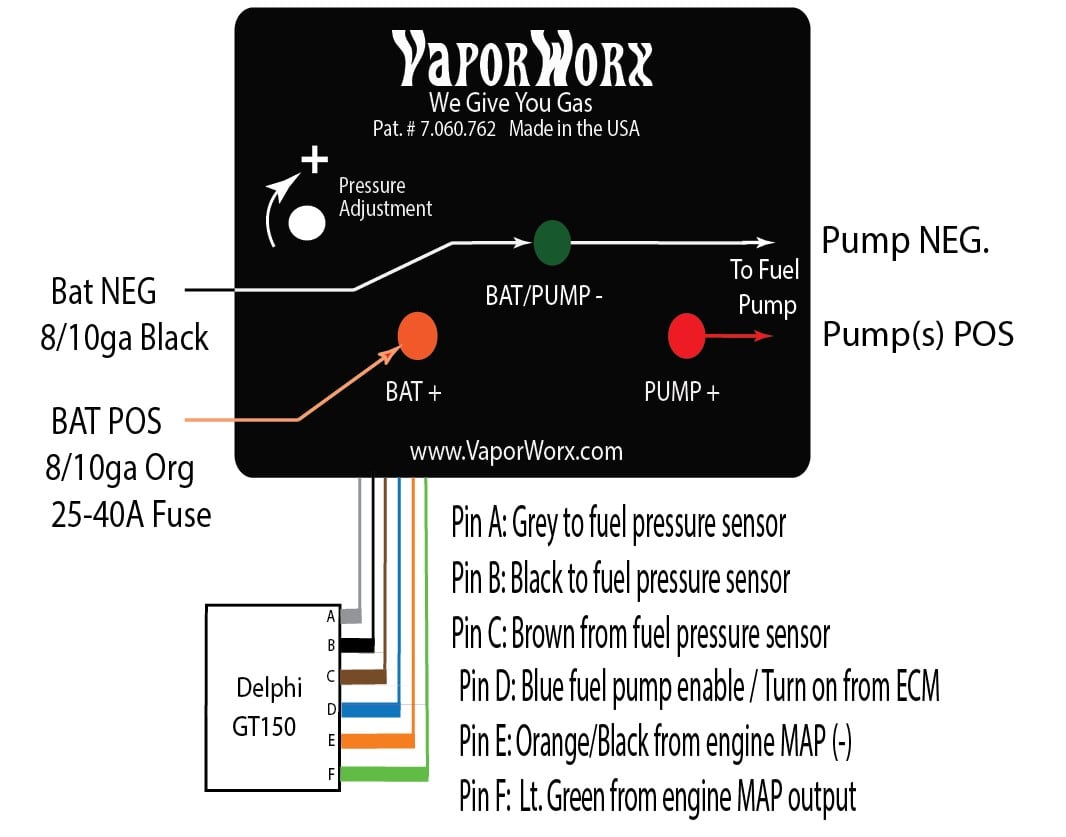

The basics for connecting the VaporWorx PWM are performed as follows:

- Connect directly from battery power to the PWM controller (+ and – in)

- Connect output power to the fuel pump using the pre-installed OE sealed Delphi/Aptiv connector (+ and – out) for GM fuel automotive fuel modules.

- Screw the pressure sensor into a 1/8”-NPT female thread on the pressure side of the fuel system near the outlet of the fuel module.

- Plug in the pre-installed OE sealed Delphi/Aptiv plug into the fuel pressure sensor.

- Connect the three-wire wire bundle from the fuel pressure sensor to the to the PWM controller using the supplied six-cavity sealed Delphi/Aptiv connector.

- Connect the orange/black ground and light green output MAP sensor wires to the six cavity connector (manifold referenced only, leave disconnected for constant pressure.)

- Connect the blue wire to the ECM fuel pump turn-on circuit. This signal is typically battery positive trigger. VaporWorx has negative trigger options available in Checkout.

Figure 2 shows the connections outlined above:

Figure 2. Basic electrical connections needed for the VaporWorx PWM controller

Figure 2. Basic electrical connections needed for the VaporWorx PWM controller

(Click the image to zoom in)

As noted earlier, the fuel pressure sensor must be located near the outlet of the fuel module or pump. As the injectors open and close, pressure pulses are developed. The fuel pressure sensor is sensitive enough, and the VaporWorx controller fast enough, to chase these pulses at idle and cruise. The length of fuel line and the column of fuel act as a pressure pulse damping system.

In extreme cases where very large pulses, or at just the right frequency+amplitude / harmonic, a Radium Engineering pulse damper may be needed.

The basic part numbering system for a VaporWorx PWM kit is:

PWZL13B

- PW = PressureWorx PWM kit assembly

- ZL1 = The fuel module the wiring is built for

- 3B = Engine MAP sensor range. Other ranges available.

Advantages:

- Very low heat generation. A minimum 50% reduction in power at idle and cruise vs. full-on systems.

- Longer pump life.

- Less electrical load.

- Lower noise.

- Simple plug-and-play design.

- Single fuel line, true returnless system.

- No return lines, filters, or external regulators for fuel module designs.

- Higher horsepower systems available (CTS-V2 + upgrade pumps).

Disadvantages:

- Possible higher cost depending on components used.

- Additional wiring.

The right PWM Kit for your build.

Using our new PWM Controller Kit Selection Tool, picking the right PWM Controller Kit for your build just got a lot easier!

Simply enter a few specific details about your build – whether you already have a fuel pumping system or not – and our tool will filter our full selection of PWM Controller Kits that fit your fuel pump/module and/or engine type!

You can also browse our full selection of PWM Controller Kits by compatibility.

Continued Reading

This article is part 9 of the 10-part informational series: Fuel Delivery Systems – An Understanding

To continue reading in the series, use the navigation below:

Or, click here to view the full navigation/table of contents for this series.

Want to know more?

Whether you have a question about the material on this page, want to know more about our products - from purchase to installation to maintenance - or anything else, contact us anytime: we're ready to talk about your ride!