Simpler & More Performance – Now Standard

In order to simplify installation and increase overall fuel system performance for dual OEM fuel module applications, VaporWorx now offers the DualX pulse width modulation controller design. This new feature will be the standard offering for all dual fuel module systems.

Supported OEM fuel modules include, but are not limited to, the following:

- Gen5 and Gen6 SS/ZL1 with the OEM fuel level sensor removed

- CTS-V2, CTS-V2 with dual DW300C/AEM equipped pumps

- GM Trucks (fuel module plug wiring changes needed)

- C7 Corvette (all models with fuel level sensor removed)

- Ford Coyote Mustang (all generations, fuel module plug wiring changes needed)

- Ford FPDM Mustangs (early 2000’s and forward using OEM FPDM equipped systems; Fuel module plug wiring changes needed)

It is strongly suggested to NOT use an inline filter with with OEM fuel modules except Gen3 Coyote GT500. Final filtering is built in. Some aftermarket fuel filters have a built-in check valve which will cause a heat-soak related overpressure condition that will lock up port type fuel injectors.

What makes the DualX different than previous controllers?

Instead of using a Hobb’s switch and relay to connect the second fuel module under higher fuel demands, the DualX instead uses a progressive ramping strategy.

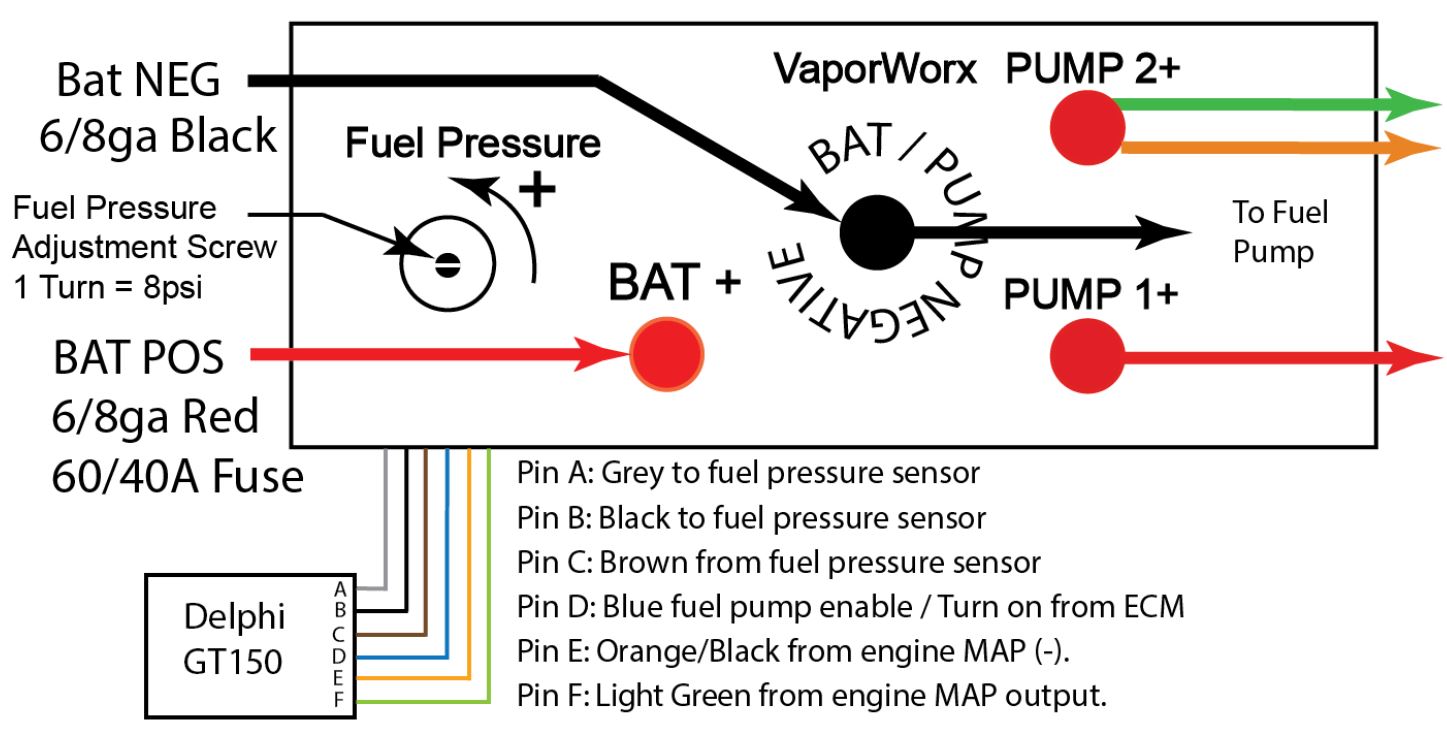

There are Pump 1 and Pump 2 connections on the VaporWorx controller for the Primary (Pump 1) and Follower (Pump 2). The Follower pump runs at lower duty cycle than the Primary. This allows the Follower pump to be on at all times, but at a lower average power. This allows the pumps in the Follower module to continually fill the reservoir with fuel so it is ready to feed the engine under the most challenging conditions.

As the Primary pump increases in duty cycle, so does the Follower. Once the Primary pump is at 100%, the Follower will continue to increase to 100% duty cycle as needed. This strategy is automatic and requires no user programming or adjustments.

Intended to be used in a manifold referenced mode, this arrangement has the same power requirement at idle and cruise as a single module running at 60psi constant, so very little heat generation. This leads to longer pump life and lower fuel temperatures. May also be used in constant pressure mode for the LT series of direct injected applications.

Features of the kit include:

- Everything needed electrically to drive dual CTS-V2 fuel modules. Can be used with ZL1 fuel modules with the OEM fuel level sensor removed. No relays, Hobb’s switches, or filters needed.

- Unmatched low fuel level capability.

- Up to 2/3 reduction in power to the fuel modules during idle and cruise vs traditional systems.

- 80A minimum continuous power rating in a compact controller package. Total size 4.5”L x 3.5”W x 2”H.

- Can be used with high-power DW300C and AEM CTS-V2 replacement pumps.

- Over-temperature shutdown with automatic reset.

- Short circuit protection that will operate indefinetely without damage.

- OEM Delphi/Aptiv connections for terminals, seals, and connector bodies where appropriate.

- 20′ wiring harness to the fuel modules.

- All cross-linked polyethylene wiring.

- UL94 rated components used throughout.

- Integrates into the OE ECM to allow all safety systems to remain functional.

- Can be used in constant or manifold referenced fuel pressure modes. Manifold referenced suggested to further reduce electrical demand.

The basic wiring layout is shown in the following diagram:

SKU: PWDXCTSV3B

This product has dedicated documentation available:

Click the button to view the documentation, or click here for download options.

NEW! Find your perfect PWM Controller Kit

It’s easier than ever to be sure you’re getting the right PWM Controller Kit for your build! Click the button below to try out our new PWM Controller Kit Selection Tool and find the perfect kit, specifically compatible with your application, based on the options you select.